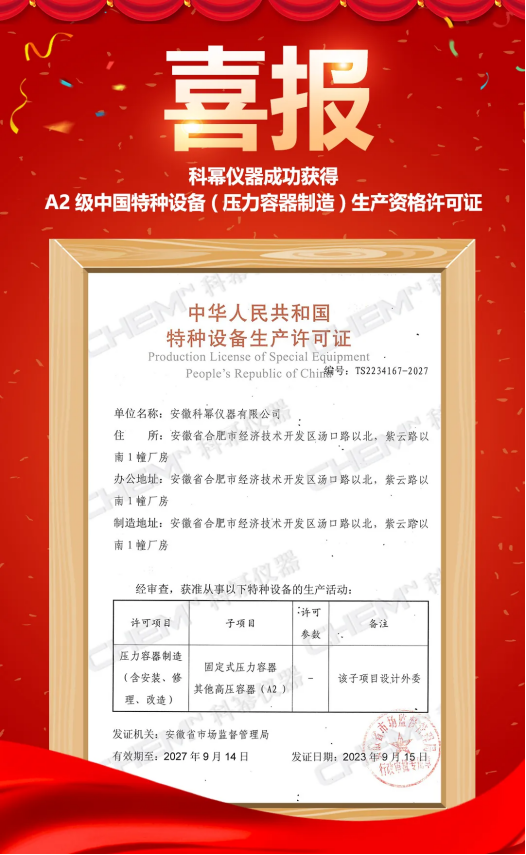

Komi Instruments successfully completed the on-site review of pressure vessel manufacturing qualifications organized by Anhui Special Equipment Safety Supervision and Inspection Institute, and recently successfully obtained the A2-level Chinese Special Equipment (Pressure Vessel Manufacturing) Production Qualification License. The acquisition of this license not only shows that our company has the qualifications and capabilities to manufacture pressure vessel special equipment, but also indicates that Komi Instruments’ pressure vessel manufacturing capabilities and technical level have been recognized and affirmed by national authoritative departments.

In order to ensure the smooth acquisition of pressure vessel manufacturing qualifications, since the preparation of this work, Ke Mi Instruments has drawn personnel from multiple departments such as the Equipment Manufacturing Center, Engineering Management Center, Technology R&D Center, Project Management Department, and Quality Management Center to form a special working group to divide the work and cooperate with each other. It focuses on continuously improving various quality assurance system documents from the aspects of licensing qualifications, quality assurance system, product safety performance, etc., and intensifies the training and assessment of responsible personnel in various positions. In accordance with relevant regulations, it makes standardized and reasonable arrangements for the production, testing, and storage sites of pressure vessels and their related materials and components, ensuring the company’s basic conditions, relevant personnel, equipment, facilities, sites and other resources.

The acquisition of this certificate is a breakthrough in the development of the company’s pressure vessel manufacturing. It is a beneficial practice for the company to continuously improve the construction of the qualification system and enhance the quality and efficiency of compliance management. It provides support for the company to further expand its business channels, open up the market, and achieve its efficiency goals. In the next step, the company will continue to promote the construction of pressure vessel manufacturing capabilities, continuously improve its manufacturing capabilities through technological and application innovation, and continue to uphold the spirit of “rigorous professionalism, innovation and efficiency, excellence, and value creation” to provide scientific researchers with safer, more convenient, accurate, and efficient scientific research instruments.

Class A2-Special Equipment Manufacturing License (Pressure Vessel)

Special equipment manufacturing license, namely TS certification, refers to the State Administration for Market Regulation’s supervision and inspection of the production (including design, manufacturing, installation, modification, maintenance and other projects), use, inspection and testing of special equipment, granting business licenses to qualified units and authorizing them to use the TS certification mark.

Special equipment manufacturing license (pressure vessel) levels are divided into:

A: Ultra-high pressure vessels, high pressure vessels (A1); Class III low and medium pressure vessels (A2); On-site welding of spherical storage tanks or spherical shell plate manufacturing (A3); Non-metallic pressure vessels (A4); Medical oxygen chambers (A5);

B: Seamless gas cylinders (B1); Welded gas cylinders (B2); Special gas cylinders (B3);

C: Railway tank cars (C1); Tank trucks or long tube trailers (C2); Tank containers (C3);

D: Class I pressure vessels (D1); Class II low and medium pressure vessels (D2).

Pressure vessels are divided into three categories according to their pressure level, type, toxicity of the medium and explosion hazard. The following are classified as Class III pressure vessels:

(1) High-pressure vessels;

(2) Medium-pressure vessels (only for extremely and highly toxic media);

(3) Medium-pressure storage vessels (only for flammable or moderately toxic media, and the PV product is greater than or equal to 10Mpa·m³);

(4) Medium-pressure reaction vessels (only for flammable or moderately toxic media, and the PV product is greater than or equal to 0.5Mpa·m³);

(5) Low-pressure vessels (only for extremely and highly toxic media, and the PV product is greater than or equal to 0.2Mpa·m³);

(6) High-pressure and medium-pressure shell and tube waste heat boilers;

(7) Medium-pressure glass-lined pressure vessels;

(8) Pressure vessels made of materials with a relatively high strength level (referring to pressure vessels with a lower limit of the specified value of the strength in the corresponding standard greater than or equal to 540 MPa);

(9) Mobile pressure vessels, including railway tank cars (the medium is liquefied gas, cryogenic liquid), tank trucks [liquefied gas transport (semi-trailer) trucks, cryogenic liquid transport (semi-trailer) trucks, permanent gas transport (semi-trailer) trucks] and tank containers (the medium is liquefied gas, cryogenic liquid), etc.);

(10) Spherical storage tanks (volume greater than or equal to 50 m³);

(11) Cryogenic liquid storage containers (volume greater than 5 m³).

Kemi Instruments – Accelerate scientific research with expertise and quality

Anhui Kemi Instrument Co., LTD. is a national high-tech enterprise specializing in the research and development and manufacturing of scientific research instruments and equipment.Relying on the strong R&D strength of the University of Science and Technology of China, we have independently developed a number of scientific research instruments with independent intellectual property rights.KeMi products have been successfully installed in all domestic “985” and “211” university laboratories and are exported overseas. The products cover more than 1,000 scientific research institutions at home and abroad.