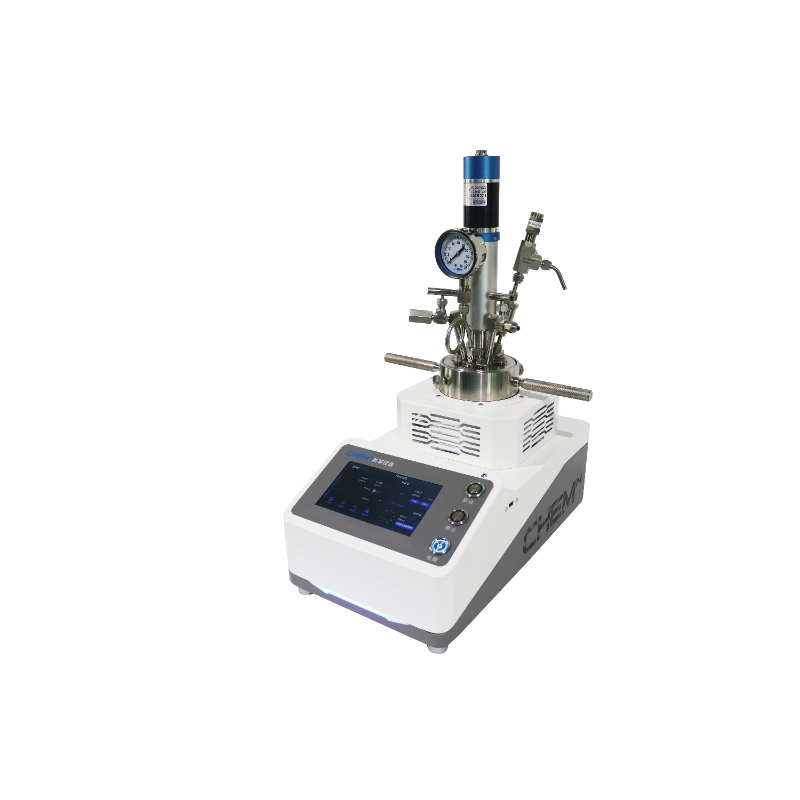

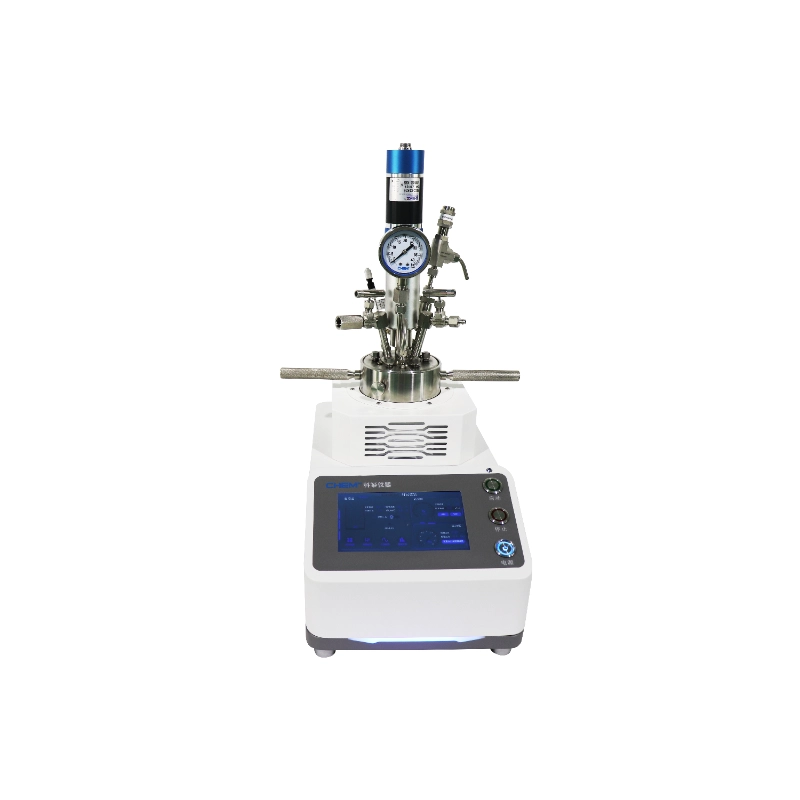

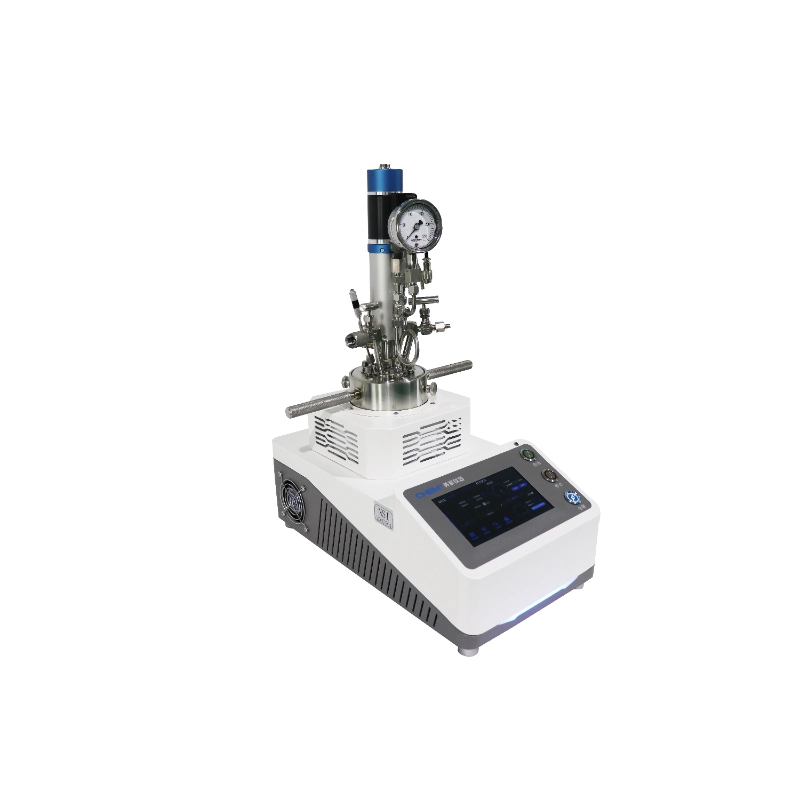

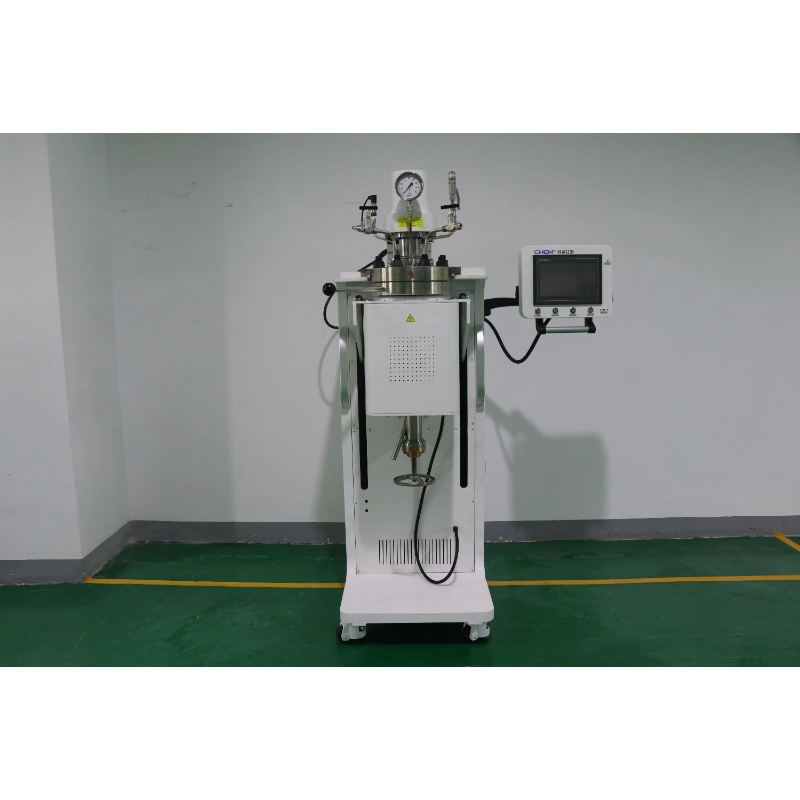

Technical Parameters

| Design volume | 25 mL, 50 mL, 100 mL, 300 mL, 500 mL |

| Maximum operating temperature | Standard 300 ℃ |

| Heating mode | Embedded stainless steel heating module |

| Heating power | 1 kW |

| Stirring speed | 400-1400 rpm (stepless speed regulation) |

| Stirring method | High-torque magnetic coupling stirring |

| Design pressure | Standard 207 bar (optional) |

| Material of reactor | 316 L stainless steel, Hastelloy C-276,etc.(optional) |

| Universal Micro Reactor Controller | Over-temperature automatic power-off, over-pressure buzzer alarm 7-inch touch screen, displaying the temperature, rotation speed,pressure and operating time USB interface, supporting data export Power supply configuration: 200 – 240 V/AC, 50 – 60 Hz Outline dimension: about 250*460*410 mm |

| Personalized options | Various alloy materials, stirring forms, sampling and cooling, etc.optional configurations |

| Outline dimension | MSG25/50/100 mL: 372*400*600 mm |

The Selection of Kemi reactor could be based on the following four basic parameters.

(1) Maximum working pressure

The design working pressure is 207bar for reactor < 500ml, 103bar for Photocatalysis reactor. Kemi produce the reactor whose maximum working pressure is 345bar. Kemi could also produce customized reactor according to different requirements.

(2) Maximum operating temperature

The design operating temperature of the conventional reactor is 300℃ (sealed with reinforced PTFE flat gasket) and maximum temperature is 550℃ (sealed with Grafoil graphite gasket), the operating temperature can be adjusted according to customer requirements.

(3) Capacity selection

The capacity of Kemi reactor ranges from 10ml to 29L. The volume here refers to the maximum volume of the reactor, Generally, the liquids should not exceed 2/3 of the volume of the reactor.

(4) Material selection

The material of Kemi regular reactor is 316L stainless steel and Hastelloy C-276, and other materials are also available:

– Industrial Titanium TA2

– Zirconium alloys 702, 705

– Other required metal materials

Kemi Reactors and Pressure vessels could meet most demands of chemical experiments for high temperatures and pressures reaction environments.

Different design solutions can be provided according to different requirements. Kemi will provide conventional configuration if there was no special requirements. For special requirements, please communicate with us and our technician can give you good solution.

Product Details

Safety

Adopt integrated shaping structure;

Tenon-groove type main sealing structure;

Over-temperature automatic power-off;

Fitok needle valve for air inlet and outlet control;

Fitok import relief valve and customized rupture valve, providing double protection.

Efficient

Quick-opening structure;

Power-assisted disassembly tools;

7-inch sensitive touch screen;

Concise and intuitive UI man-machine interface;

USB interface for data download.

Accurate

Intelligent PID temperature control mode;

Digital display stepless speed regulation;

Embedded heating module with faster heat transfer.

Portable

Integrated design;

V-stem portable needle valve with customized coating;

Minimize the weight of the reactor on the premise of ensuring safety.

Package and Factory Overview