The 91st China International Pharmaceutical API/Intermediates/Packaging/Equipment Fair (API China) will be held at the Xi’an International Convention and Exhibition Center from October 16 to 18. As an industry feast in the field of Chinese pharmaceutical industry, we will work together with pharmaceutical professionals and go all out to cooperate with more than 1,000 pharmaceutical raw materials, intermediates, pharmaceutical excipients, pharmaceutical packaging, pharmaceutical equipment, pharmaceutical R&D outsourcing, production outsourcing, and biopharmaceutical supply chain companies, more than 5,000 pharmaceutical manufacturers across the country, and nearly 30,000 colleagues in the pharmaceutical industry to innovate and cooperate to find opportunities.

Invitation letter from Kemi Instruments

At this conference, Kemi Instruments has set up a special booth in the exhibitor area (booth number: 2H32), and will bring a variety of new equipment to the exhibition. This series of equipment can be widely used in small and medium-sized trials and industrial synthetic reaction research in the pharmaceutical industry. During the conference, there will also be live broadcast interactions and rich prizes. We look forward to your visit to the Kemi Instruments booth to exchange ideas and participate in the event.

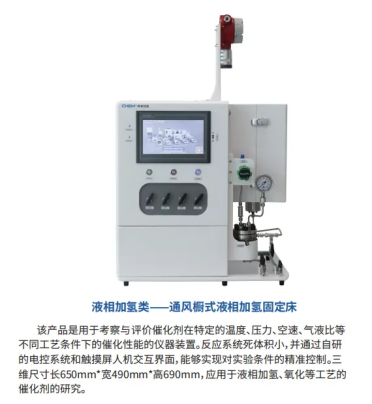

New product launch – Fume hood type liquid phase hydrogenation fixed bed

Pilot and industrial kettle equipment

Polymerization foaming kettle equipment

The nitrogen or carbon dioxide gradually penetrates into the polymer blank through static diffusion, serves as a foaming agent, passes through a nitrogen booster pump or a carbon dioxide liquid booster pump, enters the kettle and contacts the polymer, and forms a uniform melt/foaming agent homogeneous system. Applicable polymer systems are thermoplastic elastomer polymer materials, such as polyurethane (TPU), polyether block polyamide (PEBA), ethylene-vinyl acetate copolymer (EVA), etc. Advantages: It can quickly increase and reduce pressure. It takes about 3-5 minutes for a 1L foaming kettle to increase the pressure to 15Mpa, and about 5S for depressurization. It can achieve extremely fast heating and cooling in the oil bath.

Multi-channel fixed bed equipment

In order to greatly improve the efficiency of catalyst activity evaluation and kinetic research, the multi-channel fixed bed independently designed by Kemi can be equipped with multi-channel switching valves (2~8 channels), and can be coordinated with the gas chromatograph in time sequence to quickly carry out different process conditions ( temperature, space velocity, raw material ratio, etc.) or the performance evaluation and analysis of different catalysts under the same process conditions. Compared with conventional single-channel testing, significant efficiency has been achieved in catalyst screening, evaluation, testing, process development, and process optimization. and technical advantages.

Skid-mounted pilot synthesis equipment

The main body of the high-temperature and high-pressure experimental kettle and its auxiliary systems are made of stainless steel 316 forgings. The supporting equipment includes Ke Mi’s self-developed large-torque magnetic coupling agitator. The kettle body is heated by a high-temperature circulating oil bath in a jacket, and is equipped with an explosion-proof high and low temperature circulation all-in-one machine.The MCGS IoT screen is used to control and monitor the equipment, and the explosion-proof grade of the control cabinet and external electrical components is ExdⅡBT4.This polymerization reactor can be used for chemical synthesis reactions in laboratories or small-scale production. It is widely used in research and production in chemical, pharmaceutical, food, dye and other fields.Specific applications include organic synthesis, catalytic reaction, polymerization reaction, solvent synthesis, extraction, distillation, crystallization and other chemical processes. Users can choose different types of reactors according to specific needs to meet different reaction conditions and requirements.

The Komi skid-mounted synthesis system can be designed and customized according to user needs, covering the needs of pilot synthesis with an annual output of 100 kilograms to 100 tons, and meeting the requirements of various explosion-proof levels, with a volume of 1L-5000L.

Meet Changan in Xi’an

Meet Kemi Instruments in API China

91st API China

See you in Xi’an from October 16th to 18th!

Kemi Instruments sincerely invites you to join us!

Booth number: 2H32

The official Douyin live broadcast of Ke Mi Instruments will go straight to the exhibition site, come and make an appointment!