From June 19 to 21, 2024, CPHI & PMEC China 2024 will shine again at the Shanghai New International Expo Center with a large exhibition area of 210,000 square meters. The exhibition will adhere to the mission of accelerating the quality, efficiency and power transformation of my country’s pharmaceutical industry, and continue to help Chinese pharmaceutical companies accelerate their integration into the global pharmaceutical innovation chain, industrial chain and supply chain, and provide strong support for building a new development pattern of mutual promotion of domestic and international dual circulation.

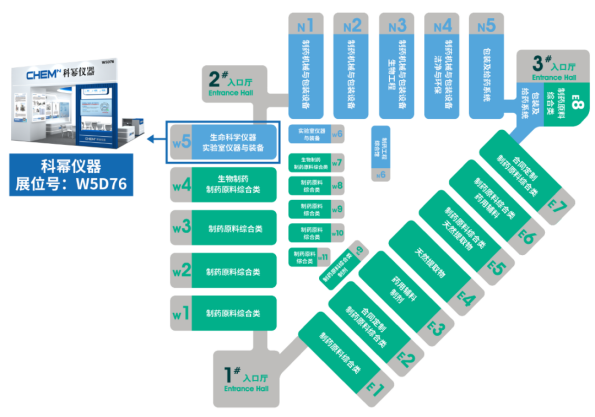

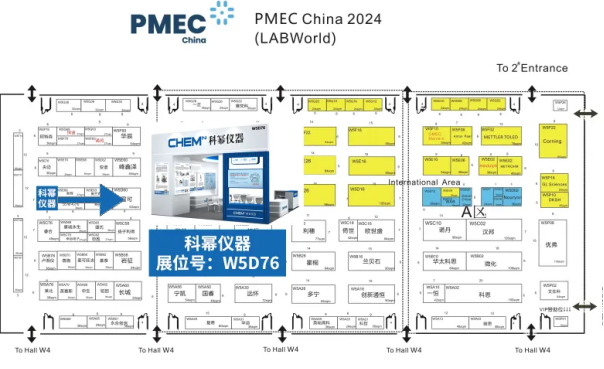

Invitation letter from Kemi Instruments

At this conference, Kemi Instruments has set up a special booth (booth number: W5D76) in the exhibitor area, and will bring a variety of new equipment to the exhibition. This series of equipment can be widely used in small-scale synthetic research in the pharmaceutical and chemical industries. During the conference, there will also be live broadcast interactions and hourly lucky draws with rich prizes. We look forward to your visit to the Kemi Instruments booth to exchange ideas and participate in the grand event.

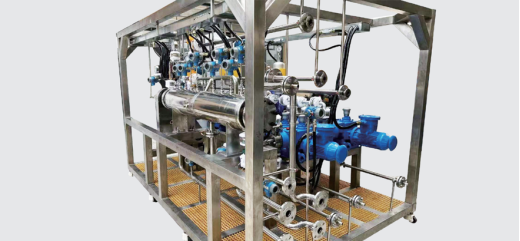

Continuous flow synthesis reaction device

1. Fixed bed reactor

Environmental protection direction – VOCs catalytic evaluation device

The device is used to study the catalytic treatment process of VOCs with different concentrations, explore the best process parameters, and then guide industrial production, save production costs, and improve work efficiency. The liquid raw material is measured by an electronic scale and pumped into the preheater by a metering pump for preheating and gasification; if the flow rate is low, the bubbling method is used to use inert gas to carry the liquid vapor. The gaseous raw heat insulation box, the reaction mixture is expected to be measured by the mass flow meter and then directly enter the fixed bed reactor after preheating, and contact with the catalyst in the reactor for reaction. The tail gas generated by the reaction passes through the back pressure valve (it can also directly enter the gas-liquid separator for cooling, the liquid phase products are collected, and the gas phase is absorbed and dried, and then goes to chromatographic analysis).

Ammonia decomposition, carbon dioxide reforming, etc. – multi-channel fixed bed

In order to greatly improve the efficiency of catalyst activity evaluation and kinetic research, the multi-channel fixed bed independently designed by Kemi can be equipped with multi-channel switching valves (2~8 channels), and can be coordinated with the gas chromatograph in time sequence to quickly carry out different process conditions ( temperature, space velocity, raw material ratio, etc.) or the performance evaluation and analysis of different catalysts under the same process conditions. Compared with conventional single-channel testing, significant efficiency has been achieved in catalyst screening, evaluation, testing, process development, and process optimization. and technical advantages.

2. Microchannel Reactor

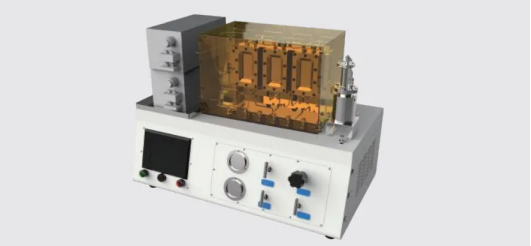

K1-level integrated photothermal multifunctional microchannel reactor

The K1-level small-scale microreactor is an innovative scientific research microchannel continuous flow reaction equipment launched to meet the research and development needs of microreaction technology. It is also the only commercial instrument on a desktop instrument that fully integrates functions such as gas-liquid feeding, high and low temperature integrated temperature control, microreaction unit, 9-wavelength adjustable LED photocatalytic light source and automatic back pressure adjustment.

K2-class four-temperature zone fully integrated microchannel reactor

The K2-level fully integrated small-scale microreactor is a representative product of the fully integrated microreactor system. With the technical advantages of independent research and development of the entire stack of microreactor technology, the reactor integrates the microreactor unit, feeding system, dual-way feeding precooling/heating system, dual-temperature zone high and low temperature integrated circulation system and touch screen automatic control system in a body less than 1.5m wide, thus freeing researchers from the constraints of various external supporting equipment of the microreactor and truly realizing the plug-in and use of the microreactor equipment.

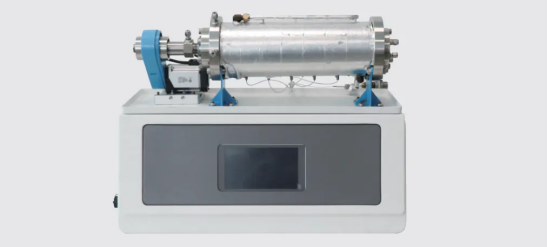

3. Dynamic tubular reactor

D1-level small-scale rotary cutting microfluidic field tubular reactor

The D1 reactor has a moderate liquid holding capacity, compact design, good sealing, precise temperature measurement, and convenient control. It is particularly suitable for universities, research institutes, and corporate R&D departments to carry out continuous flow reaction experimental research and kilogram-level synthesis.

D3/D4 industrial rotary cutting microfluidic tubular reactor

The D3 pilot-scale rotary microfluidic field tubular reactor and the D4 industrial-scale rotary microfluidic field tubular reactor can flexibly choose single-end mechanical seal, double-end mechanical seal (with automatic pressure compensation) and magnetic coupling transmission seal structure as needed. The D3/4 reactor can also realize the combination of magnetic coupling transmission seal and internal and external double heat exchange, breaking the limitations of the traditional structure of stirred tubular reactors that mechanical seals cannot adapt to high-pressure reactions and have leakage rates, and magnetic coupling seals cannot achieve internal and external double-sided heat exchange.