Technical parameters

| Model | TFH-1200-50-Ⅲ-200 |

| Maximum temperature | 1,200℃ (short-term) |

| Rated temperature | 1,100℃ |

| Temperature control accuracy | ±1℃ |

| Size of furnace tube (tube furnace) | φ50 (OD) *1,000 mm (customizable) |

| Heating zone length | 3*200mm |

| Constant temperature zone length | 400mm (±2℃) |

| Control system | PID control and self-tuning adjustment function Intelligent 30-segment programmable control With over-temperature and broken couple alarm function K-type thermocouple |

| Heating element | Electric resistance wire |

| Heating rate | ≤10°C/min |

| Rated power | 6kW |

| Adaptive power | AC220 V50/60 HZ |

| Outline dimension | 1350x420x520mm |

| Weight | 75 kg |

| Precautions for use | The gas pressure in the furnace tube cannot be higher than 0.02MPa; Since the gas pressure inside the gas cylinder is relatively high, a pressure reducing valve must be installed on the gas cylinder when the gas is introduced into the furnace tube; When the furnace body temperature is higher than 1000℃, the furnace tube cannot be in a vacuum state, and the gas pressure in the furnace tube must be equivalent to the atmospheric pressure and maintained at normal pressure; The gas flow rate entering the furnace tube must be less than 200SCCM to avoid the impact of cold air flow on the heated quartz tube; The long-term use temperature of the quartz tube is <1100℃; For the experiment of sample heating, it is not recommended to close the exhaust valve and the air inlet valve at the flange end of the furnace tube. If you need to close the gas valve to heat the sample, you need to pay attention to the indication of the pressure gauge at all times. If the pressure indication is greater than 0.02MPa, you must immediately open the vent valve to prevent accidents (such as furnace tube rupture, flange flying out, etc.). |

Product features

1. Yudian AI-3756P (7-inch) colorful touch screen human machine interface is adopted for temperature control.

2. The double-layer air cooling structure of the shell keeps the surface temperature ≤ 60 ℃.

3. Real-time USB data export.

4. The chamber is made of high purity alumina microcrystallite fiber subject to vacuum forming under high temperature,providing a uniform hermal field that can save energy by more than 50%.

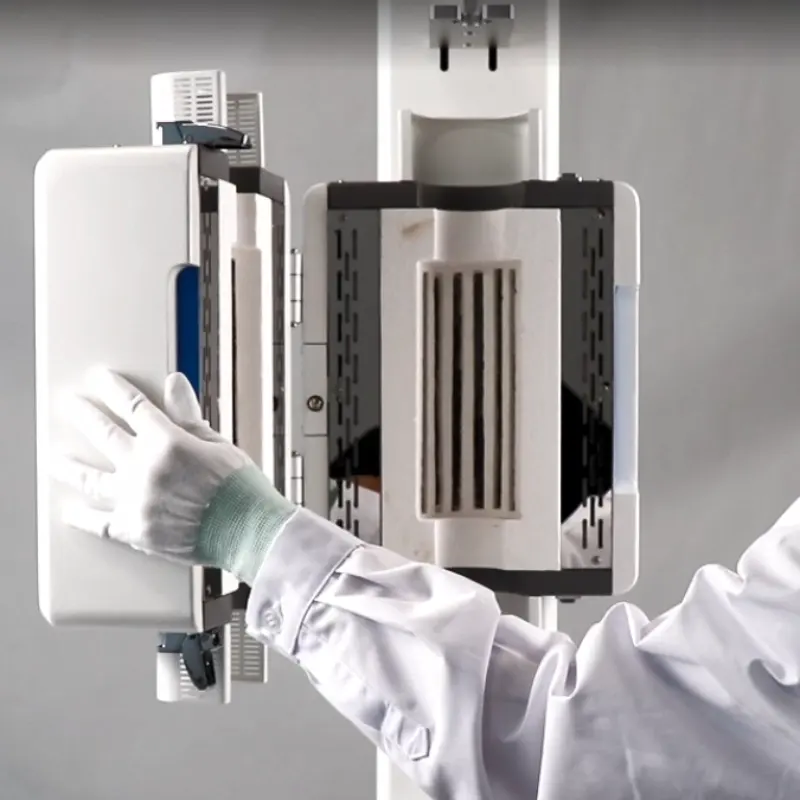

5. The quick-opening flange structure enables to operate easily.