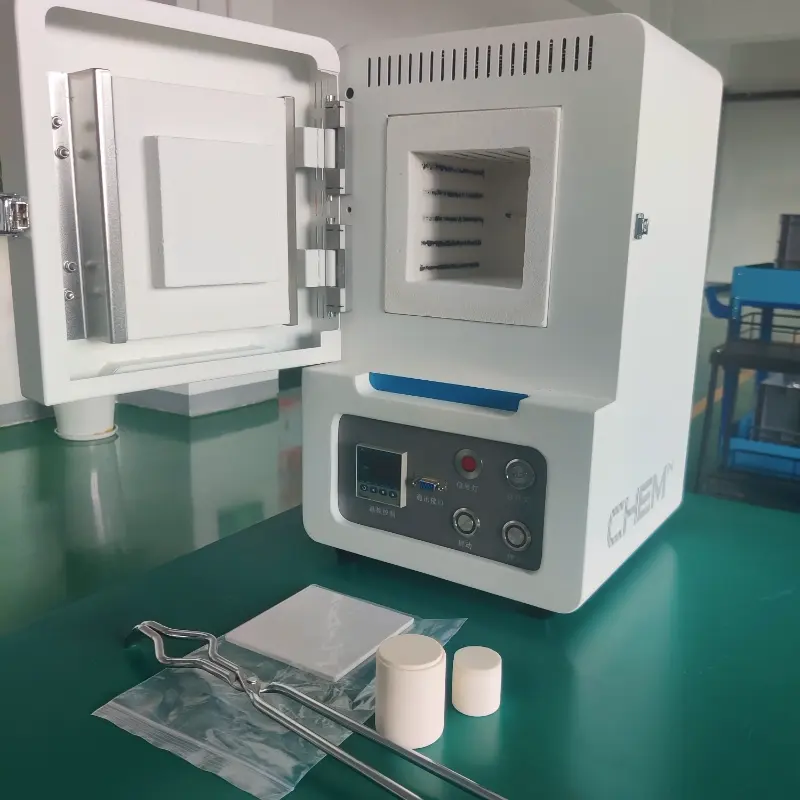

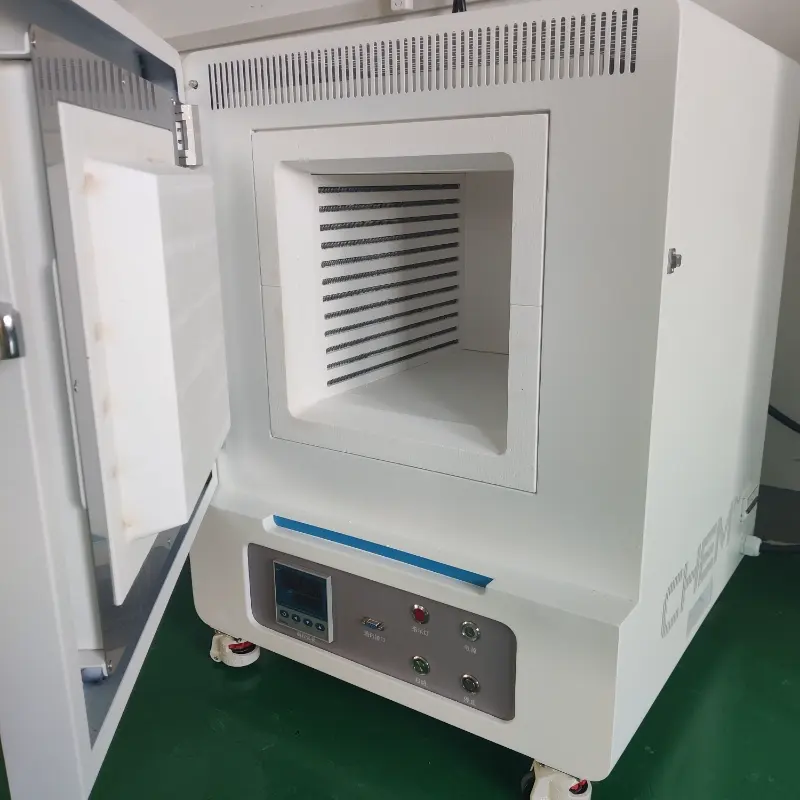

Technical Parameters

| Model | BFC-1200-7.2L |

| Max temperature | 1200℃ |

| Heating rate | ≤20℃/min |

| Temperature control precision | ±1℃ |

| Furnace capacity | 300*200*120mm(7.2L) |

| Power | 3KW |

| Thermocouples | K type |

| Heating element | Electric Resistance Wire |

| Adaptive power supply | AC220V 50/60HZ |

| Temperature control | Fuzzy PID control and self-tuning regulation, intelligent 30-segment programmable control, with over-temperature and broken-couple alarm function. |

Product Features

(1) The heat preservation material adopts vacuum adsorption molding of alumina fiber inorganic material, the surface is coated with high temperature alumina coating imported from the U.S.A., which is environmentally friendly and energy-saving.

(2) Adopting PID intelligent control, the temperature control precision can be up to ±1°C.

(3) The furnace body adopts double-layer air-cooling mechanism, the surface temperature of the shell is lower than 60°C when the furnace burns to the highest temperature.

(4) The use of a variety of thermal insulation materials made of a combination of small size furnace, energy consumption (power consumption is a quarter of the power consumption of similar products)

LONG SERVICE LIFE

Vacuum adsorption molding of alumina fiber inorganic materials, heating element for the electric group wire (Beijing Shougang HRE)

INORGANIC MATERIAL

Double-layer sheet metal, hot chamber + furnace liner + insulation layer + inner liner + air insulation layer + shell. There is also fan forced cooling between the inner liner and the outer shell, which greatly improves the problem of hot stove shell.

PID CONTROL

Adopt fuzzy PID control to control temperature with accuracy up to 1℃.

DOUBLE-LAYER AIR-COOLED MACHANISM

Furnace body adopts double-layer air-cooling mechanism, when the furnace burns to the highest temperature, the surface temperature of the shell is less than 60°C.

INSULATION MATERIALS

Adopting a variety of thermal insulation materials, the furnace is small in size and consumes less energy (power consumption is 1/4 of the power consumption of similar products).

Factory Overview